45 Ton Aluminium Foil Container Machine

Product Details:

- Type Automatic Aluminium Foil Container Machine

- Material Stainless Steel

- Computerized Yes

- Control System PLC Control

- Cutting Speed 3600-6000 Km/hr

- Cutting Thickness 100 Millimeter (mm)

- Voltage 380 Volt (v)

- Click to View more

45 Ton Aluminium Foil Container Machine Price And Quantity

- 1 Unit

45 Ton Aluminium Foil Container Machine Product Specifications

- Automatic Aluminium Foil Container Machine

- 3600-6000 Km/hr

- Stainless Steel

- 7000 Kilograms (kg)

- Yes

- 1915*1280*2500 Millimeter (mm)

- PLC Control

- 380 Volt (v)

- 100 Millimeter (mm)

45 Ton Aluminium Foil Container Machine Trade Information

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- 1 Unit Per Week

- 1 Week

- Wood Pallet

- North America, Eastern Europe, Middle East, Africa, Central America, South America, Western Europe, Asia, Australia

- All India

Product Description

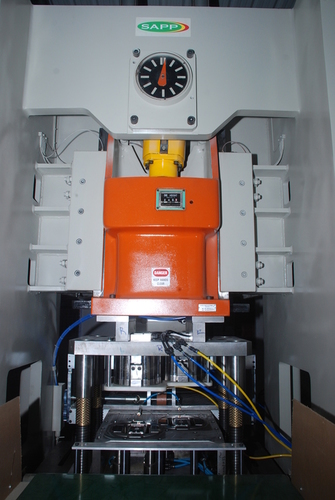

45 Ton Aluminium Foil Container Machine

The whole production line includes: Feeding Machine, Press Machine, Moulds, Automatic Stacker, Scrap Collector

Features:

This machine adopts programmable logic controller (PLC) as the controlling system.it’s reliable. The feeding length, producing speed and other parameter are easily set, this is integration of Air and Electrical centralized control, automated production.The feeding is controlled by servo system, the feeding length is accurate And can be adjusted freely from 20mm to 999m.The accurate press adopts steel plates joining body, variable frequency speed regulation, dry type friction clutch-on-off, Hydraulic over-load protector to protect the press.In short, this is a high accuracy and reliability production line for aluminium foil containers.

Product Line Operating Requirements:

- Pressure: 630KN

- Body work plate hole dimension: 325*400mm

- Stroke time: 60-100times/min(3600—6000pcs/hour for one cavity mould)

- Stroke height: 220-240mm

- Work plate thickness: 100mm

- Max. die Installation height: 420mm

- Motorised slide adjustment

- Dimension of slide block bottom, size of handle hole:320*145mm,18

- The distance from the center of slice to the body: 450mm

- The height adjustment for die: 80mm

- Bloster Size 1100*900*100mm

- Die handle hole dimension: 50*60mm

- Work plate dimension: 660*1000 mm

- Dimension: 1915*1280*2500mm (L*W*H)

- Motor capacity:7.5KW

- Net weight: 7000kg

- Power supply AC three phase Voltage:380V

- Air consumption: 1m3/min, 0.6-1MPa

Feeding Machine:

- Max. Material roll diameter: 800mm

- Max, Material roll width: 700mm

- Feeding Speed: 20-50M/min

- Feeding length: 30-999mm

- Feeding tolerance: +/-0.3mm

- Capacity:1kW

- Voltage: 380V

- Net Weight: 800kg

- Dimension: 1270*1250*800mm (L*W*H)